Jan 9, 2011

Mercedes C63 AMG Brabus Paint Correction

– Quartz Ceramic Coating

This Mercedes 2008 model C63 AMG tuned by Brabus, went through a extensive Paint Correction. With a tough Ceramic Clear Coat, it was measured properly to ensure safe amounts of clear coat were only levelled down. A 3 stage 24 step wash was to ensure a good wash was carried through all areas of the exterior.

Swissvax imported brushes cleaned all Badged Emblems of oxidation, followed by a Iron X Decontamination clean. Wheels were also thoroughly cleaned with extension brushes reaching into the deep wheel wells that are usually hard to reach with the normal hand wash.

A extensive Clay-bar rid ferrous particles that have bonded to the exterior. After this stage, it was really evident that the paintwork had the normal levels of swirl marks, caused by poor washing techniques.

In this detail, total hours spent was roughly 22 Hours spread over 3 Days. These are the selected pictures chosen from over 200 clicks during the detail process with a Canon SLR. I couldn’t put them all up, but alot of footage on the video shows evident details of the “detail” and process i went through to gain such a final result. This Detail was a bespoke detail that consists of the “Ultimate Concours Paint Correction Detail” found in the Paint Correction Page. Not only did it receive a Ceramic Quartz 9H coating, but 2 coats were applied. In short, Quartz ceramic Coating is a “sacrificial layer” that is roughly 2 microns in thickness, and is chemical resistant, hydrophobic, and is a scratch resistant coating. Minor touches from plastic rejuvenation, windows sealed with a glass sealant, light interior detail and a Rim Wax was applied to the exterior surface of the “Brabus” Wheels. Car Detailing Melbourne – 0405662881

Pre-Wash & Decontamination Process

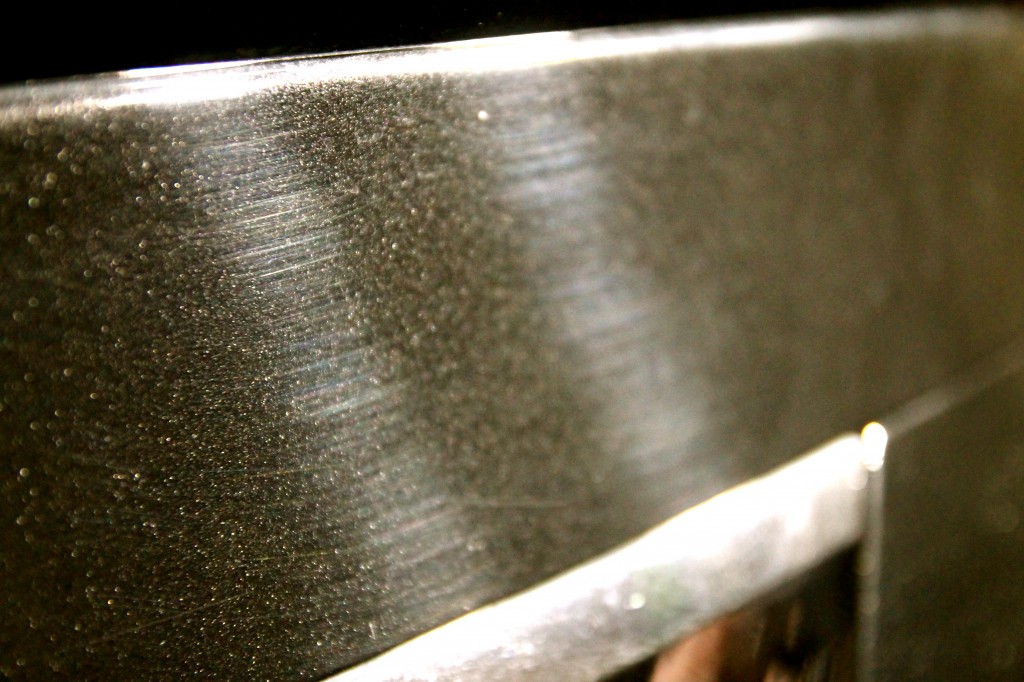

Evident Scuff Marks & Swirl Marks

Wheels are washed with a PH+neutral Shampoo, followed by Iron X de-contamination

Before – Slight swirl marks & scratches on front bumper

After – Extensive Polish to refine clear coat of any slight swirl marks or light scratches (Flawless – Metallic Colour Starts to Jewell)

Before – Swirl Marks on Bonnet

After – Flawless Finish on Bonnet

Before – Driver Side Lower Wheel Arch – Evident signs of Swirl marks/light scratches

Before – Evident Swirls & Scratches on Rear Wing

After – Rear Wing After Polishing (Correction Complete)

After – Rear Boot After Polishing (Correction Complete)

Before – rear Boot

Before – rear Boot

Before – rear Boot

Before – rear Boot

After – rear Boot

Before – Passenger side Rear door

After – Passenger side Rear door

After – Passenger side Rear door

Before – Pillar with Swirl marks or Light scratches

After – Pillars are rid of light scratches

IPA Fluid is Used during polishing to ensure all swirl marks are eliminated and that no oils from polishes are masking any potential swirl marks.

IPA fluid is also used so that way the clear coat is fully clean so any coatings used e.g Opticoat 9H, can properly bond to the clear coat and nothing else on top.

After

After

After

After